A company should have a long-range business strategy if it is going to maintain a competitive position in the marketplace. A business strategy is a plan for the company that clearly defines the company’s long-term goals. How it plans to achieve these goals and the way the company plans to differentiate itself from its competitors. A business strategy must leverage the company’s core competencies, or strengths, and gingerly consider the characteristics of the marketplace.

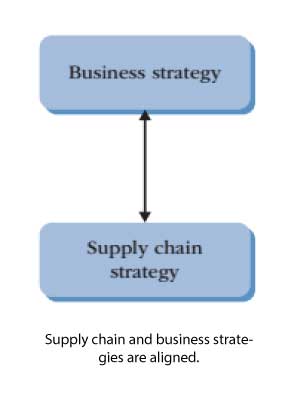

Supply chain strategy is a radical plan for the design and ongoing management of all supply chain decisions that back the business strategy. Consider that the design of a supply chain should differ based on how the company intends to compete in the marketplace. To sustain competitiveness, companies must design their supply chains to be aligned with their business strategy. To gratify the needs of the customers, take advantage of the company’s strengths, and stay adaptive. This relationship between the business strategy and the supply chain strategy is shown in the Image Below.

Consider the case of Zara, discussed Below. Zara’s business strategy is to produce and deliver look-alikes of the latest fashion trends to customers at an affordable price. Zara understands that the key to accomplishing this is through a well-thought-out supply chain strategy designed to support its goals. For this reason, the company chooses to be vertically integrated, giving it speed, flexibility, and control of product design and delivery. Also, the company chooses not to outsource most of its production, as doing so would hurt Zara’s ability to quickly adapt to fashion trends. As we can see, Zara’s supply chain strategy is designed to enable the company to achieve the goals set by its business strategy.

Zara’s business strategy

Walk into a Zara clothing store, whether in New York, Miami, Atlanta, or London, and you experience the feel of high fashion. The ambiance is contemporary, with dim lighting and the beat of modern music pulsating in the background. The clothing styles on the racks capture the latest fashion for men and women, and there is a wide array of choices. Surprisingly, however, the price point is reasonable and much lower than found at any comparable retailer or boutique. This is what makes Zara unique.

Zara is the highly successful Spanish retailer with over 2,000 stores worldwide that launches around 12,000 new fashion designs each year. It is known for its quick design and delivery, and it needs just two weeks to develop a new product and get it to stores, compared with a six-month industry average.

Zara has been called a fashion imitator. It focuses on copying the latest fashion items customers want and delivering them at a considerably lower price. Unlike other retailers, it does not advertise and does not promote the season’s trends to influence shoppers. To achieve this level of success Zara has a most unusual strategy, and its secret lies in supply chain management (SCM).

Zara is a vertically integrated retailer and controls most of its supply chain, including sourcing, design, production, and distribution. This is highly unusual in an industry that overwhelmingly tends to outsource fashion production to low-cost countries. In fact, whereas most competitors outsource all production to Asia, Zara makes over half of its merchandise at a dozen company-owned factories in Spain and Portugal, where labor is cheaper than in Western Europe.

Only items with a longer shelf life, such as basic T-shirts, are outsourced to low-cost suppliers in Asia and Turkey. A large part of this is to support its strategy of offering high-fashion items. To accomplish this, Zara designers are located on the floor of its manufacturing facility to shorten production time, and they have weekly talks with store managers across the globe to find out what customers want.

Borrowing best practices from the Toyota Motor Corporation, Zara has a very efficient and lean production process. Zara carries little inventory of expensive items. However, to give itself flexibility and offer a wide product assortment, Zara carries excess inventories of inexpensive items. This includes buttons and zippers, which Zara’s designers can use to create differences in clothing items. As a result, Zara can offer considerably greater product variety than its competitors. Also, Zara has an extremely quick design turnover compared to competitors.

New designs are developed daily—sometimes three to four a day—and quickly put into production. This short production cycle means greater success in meeting consumer preferences. If a design doesn’t sell well within a week, it is withdrawn from shops, further orders are canceled, and a new design is pursued. No design stays on the shop floor for more than four weeks, which encourages Zara’s shoppers to make repeat visits. Customers know that end-of-season markdowns, so common in the retail industry, do not occur at Zara, so they feel a greater need to buy the item they have in hand.

Zara uses its supply chain strategy as a competitive weapon. For Zara, this has proved to be a very successful decision.

Strategic Alignment

It is important to remember that there must be a strategic alignment between the business strategy and supply chain strategy. A company’s supply chain strategy must be exhibited to drive and support its business strategy. Consider an electronics company that has formulated a business strategy to compete on delivery excellence, such as order-fulfillment time. As a result, the supply chain strategy may be designed for speed of delivery, although perhaps at a higher cost.

Now imagine that the company decides to change its business strategy to compete on cost rather than delivery. Considering the current market competition and customer perceptions of value. If this change in business strategy is not communicated to SCM, the supply chain will continue to focus on delivery rather than cost. The company will continue to excel at delivery. While incurring a higher cost, and not meeting the business goals set for the company.

The supply chain should not be designed to sheer mimic its competitors or only focus on cost-cutting efforts. The supply chain should be designed and positioned to help the strategic direction of the firm, giving it a competitive benefit in the marketplace. Supply chains can have a very different design based on their competitive focus. Today’s most successful companies, as illustrated by Zara, have achieved world-class status in large part due to a skillfully designed supply chain strategy that is manifested in the design of its supply chain. Companies all over the globe understand that they cannot achieve the competitiveness needed to survive and thrive in the current global economy without strategically thinking about their supply chains.

In addition to SCM, all organizational functions should be designed to support the business strategy. This includes marketing, operations, distribution, purchasing, and even finance. In addition, organizational functions should support each other. This functional support is especially important for SCM given its boundary-spanning nature and high dependence on logistics, marketing, and operations. This functional unity and support of the business strategy will enable the organization to function in a synchronized manner.